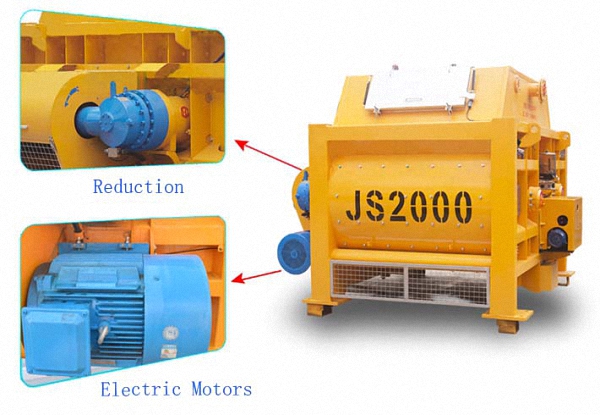

JS2000 twin shaft batch mixer is composed of feeding, stirring, discharging, water supply and electrical parts. It is a new type of twin shaft batch mixer with the domestic leading technology. It has the advantages of uniform mixing, reasonable structure, beautiful appearance, smooth operation and convenient operation. Mixing cycle time is short and a series of advantages, suitable for all types of small and medium-sized prefabricated plant and highway, bridge, water conservancy, ports, terminals and other industrial or civil engineering construction sector.

Description of Twin Shaft Batch Mixer

JS2000 twin shaft batch mixer is composed of feeding, stirring, discharging, water supply, electric and other parts. Besides, it can also be used as a simple mixing station and PLD1600 batching machine. It can also be used as host of

stationary concrete batching plant.

Characteristics of Twin Shaft Batch Mixer

1. Stir well

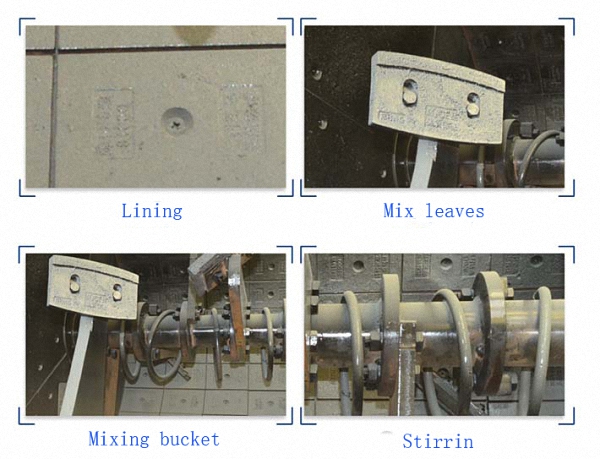

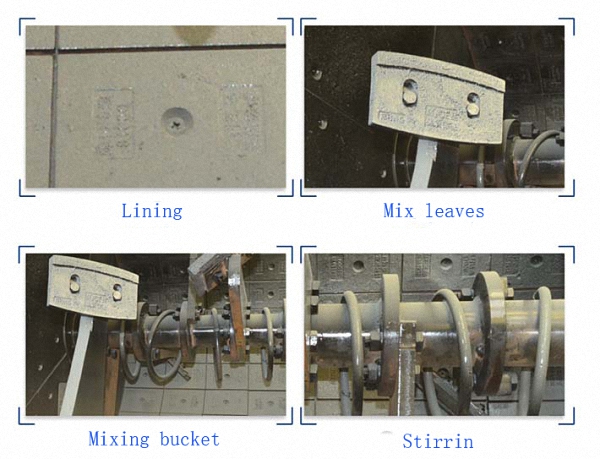

Mixing tube arc part is welded, mixing cylinder inlaid with five kinds of liner, are countersunk head screws and cylinder fastening.

2. Compact structure

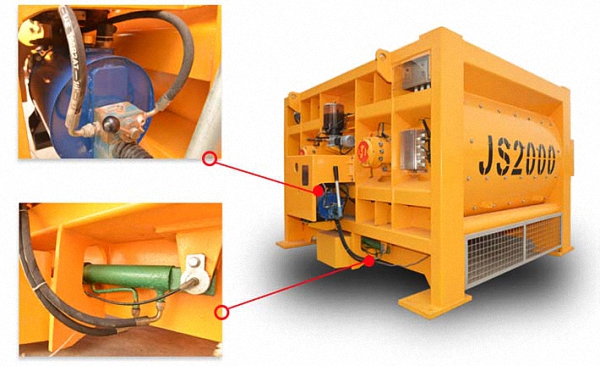

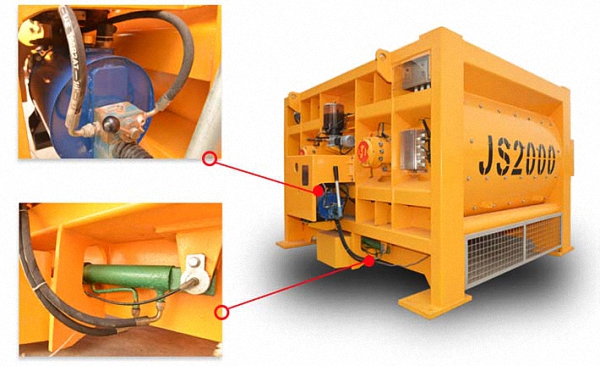

In order to ensure the quality of the seal, in the end of the mixing cylinder with a special oil supply device.

3. Powerful

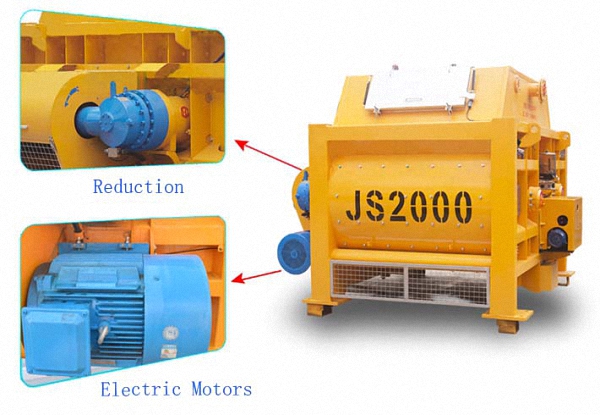

Reducer two output shafts through two pairs of open gears were driven by two horizontal configuration of the mixing shaft reverse isokinetic maneuver.

4. Easy to operate

Electrical control system all imported first-class international components, full-featured, reliable performance, easy to use.

Models and Technical Specifications

|

Item |

Charging Capacity (L) |

Discharging Capacity (L) |

Prod mini diesel beton mixer manufacturer uctivity (m3/h) |

Aggregate Size (cobble/gravel) (mm) |

Overall Dimension (LXWXH) (mm) |

|

|

|

|

|

|

|

|

JS2000 |

3200 |

2000 |

100 Min |

80/60 |

3500X2320X1677 |

|

|

|

|

|

|

|

Twin shaft batch mixer feeding system consists of hoisting mechanism, feeding rack, hopper, feeding mouth and so on.

Feeding Rack

In the loading rack is equipped with limit switches, the upper limit there are two limit switches, respectively, on the hopper from the limit and the role of safety protection. The upper part of the loading rack is foldable.

Twin shaft batch mixer motor directly connected with the cycloid reducer, reducer two output shafts, respectively, driven by the split gear horizontal configuration of the mixing shaft reverse constant speed rotation.

Twin shaft batch mixer mixing tube arc is welded into the mixing cylinder is set with five kinds of liner, are countersunk screws with the cylinder fastening connection.

Twin shaft batch mixer unloading gate installed in the bottom of the mixer, the pneumatic discharge through the cylinder, but also to control the discharge door opening and closing position, by adjusting the location of the seal can guarantee discharge door seal.